DTF Printing Supplies: UK Shop for DTF Ink & DTF Supplies

Welcome to the premier UK shop for all your DTF printing supplies! We offer a comprehensive range of high-quality DTF products, from DTF ink and DTF film to DTF powder and everything in between. Whether you're a seasoned professional or just starting out, we have the DTF printing supplies you need to achieve stunning results with direct to film technology.

Introduction to DTF Printing

What is DTF Printing?

DTF printing, or direct to film printing, is a revolutionary printing technology where designs are printed onto a special DTF film, also known as PET film, using DTF ink. This DTF transfer is then heat pressed onto various surfaces. The DTF printer uses a water-based ink to print on film and white ink to create vibrant and durable prints.

Benefits of DTF Direct to Film Technology

DTF offers printing on a wide range of fabrics with excellent wash resistance and vibrant colors. DTF direct to film technology offers numerous advantages over traditional printing methods like DTG. It allows for printing on a wide range of fabrics, including cotton, polyester, and blends, up to 60cm in width. DTF printing also boasts excellent wash resistance and vibrant colors, resulting in high-quality DTF transfers that are both durable and visually appealing, all while being cost-effective.

Applications of DTF Printing

DTF printing is versatile and applicable to custom apparel, promotional items, and personalized gifts. The applications of DTF printing are vast and varied. From custom apparel like t-shirts and hoodies to promotional items and personalized gifts, DTF direct to film opens up a world of possibilities with a direct to film printer. Businesses can offer a printing service, creating unique designs for various needs. The versatility of DTF printing makes it a popular choice for both small and large-scale operations, especially when using UV DTF technology.

Essential DTF Supplies

Types of DTF Film

Choosing the right DTF film is essential for optimal print quality, especially when using a gang sheet builder. DTF film, sometimes called transfer film, is a crucial consumable in the DTF printing process, especially when using UV DTF technology. Different types of DTF film are available, each with its own specific characteristics and benefits. Some are optimized for hot peel, while others offer superior ink adhesion. Choosing the right DTF film is essential for achieving optimal print quality with your DTF printing supplies.

Understanding DTF Ink

High-quality DTF ink is vital for vibrant, long-lasting prints and preventing clogs. DTF ink is a specially formulated water-based ink and is vital for achieving vibrant and long-lasting prints. Typically sold as an ink set CMYK, it includes cyan ink, magenta ink, black ink, and white ink to ensure high-quality DTF printing with an Epson printer. Selecting a high-quality DTF ink, specifically designed for your DTF printer, is crucial for preventing clogs and ensuring consistent print results.

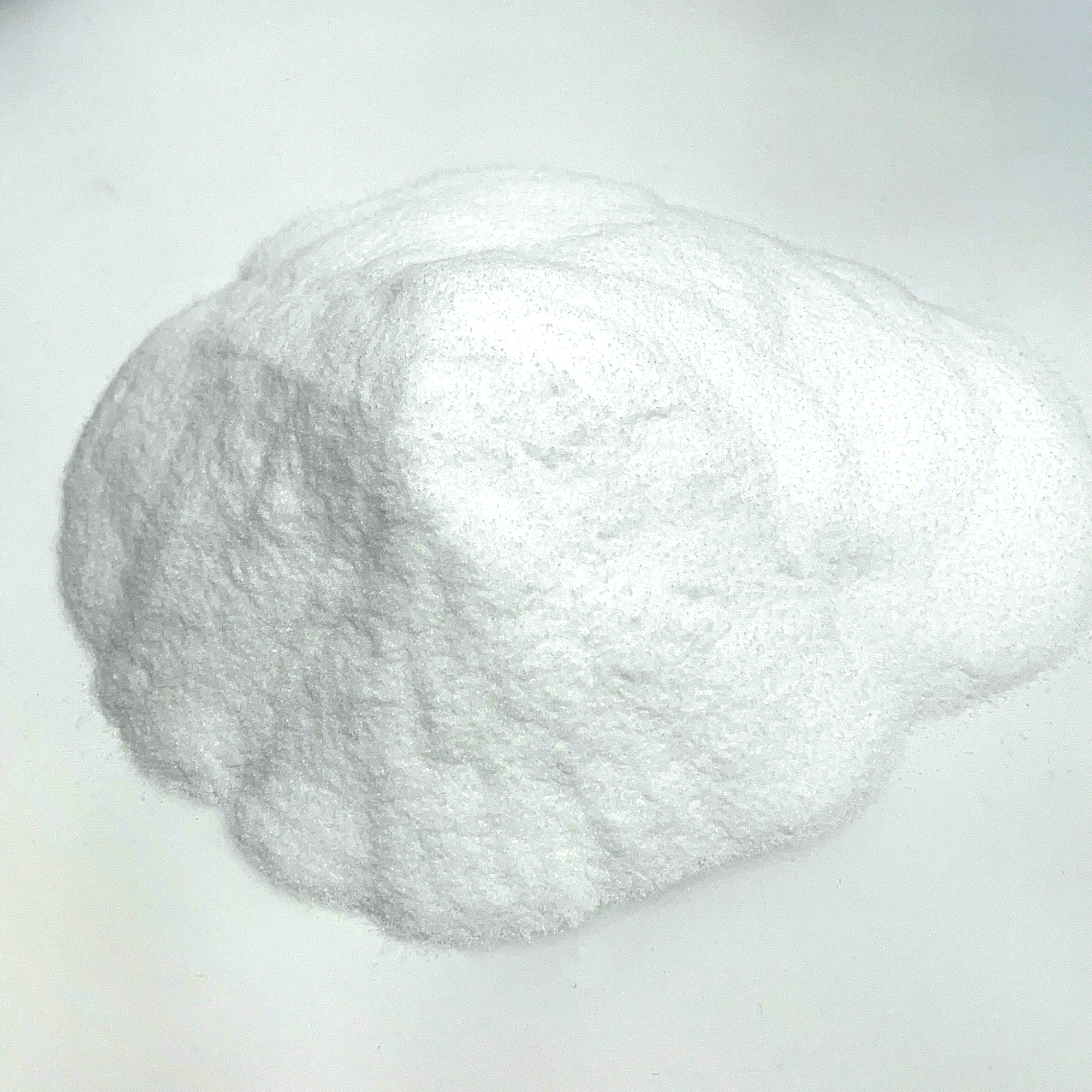

Overview of DTF Powder and Adhesives

DTF powder ensures washability and durability of the final print. DTF powder, also known as adhesive powder or DTF adhesive, is a key component in the DTF printing process. Applied to the wet ink on the DTF film, it acts as an adhesive that bonds the design to the fabric during the heat press process. Using the correct DTF powder ensures excellent washability and durability of the final print, providing a professional finish.

Choosing the Right DTF Printer

Features to Look for in DTF Printers

Look for high-resolution print heads, efficient ink delivery systems, and user-friendly software for your shop DTF projects. When selecting a DTF printer, consider several crucial features. A high-resolution print head is paramount for detailed and vibrant high-quality DTF printing. Look for models with efficient ink delivery systems to minimize waste and ensure consistent ink flow. Also, consider user-friendly software for design management and printer settings for optimal direct to film results with your printing supplies.

Recommended DTF Printers in the UK

The UK market offers a variety of DTF printer options. Epson-based DTF printers are known for their reliability and print quality when utilizing direct to film printing. Some leading DTF brands offer complete DTF printing solutions, including the DTF printer, ink, and software. Research and compare models based on your specific needs and budget to choose the best DTF printing supplies.

Comparing A3 and A4 DTF Printers

A3 DTF printers are for larger designs, while A4 are compact, affordable, and suitable for 33cm projects. Choosing between A3 and A4 DTF printers depends on your production volume and print size requirements, such as 33cm or 60cm. A3 DTF printers can accommodate larger designs and gang sheets, increasing efficiency for larger orders of DTF transfers up to 60cm. A4 DTF printers are more compact and affordable, ideal for smaller businesses or those with limited space, offering a cost-effective entry point into the world of DTF printing.

DTF Ink and Color Management

Understanding CMYK Color Model in DTF Printing

The CMYK color model is fundamental to DTF printing. The CMYK (Cyan, Magenta, Yellow, Black) color model is fundamental to DTF printing. DTF printers utilize the CMYK ink set to reproduce a wide spectrum of colors. Understanding how these colors interact is crucial for achieving accurate and vibrant prints on your DTF film. Proper color management ensures that the colors in your design translate accurately to the final DTF direct to film transfer.

Importance of High-Quality DTF Ink

High-quality DTF ink ensures vibrant colors, wash resistance, and minimal clogging. Using high-quality DTF ink is paramount for achieving exceptional print results and prolonging the life of your Epson DTF printer. High-quality DTF ink ensures vibrant colors, excellent wash resistance, and minimal clogging. Investing in reputable DTF ink brands minimizes the risk of print defects and ensures consistent, high-quality DTF printing transfers with your DTF printing supplies.

Specialty Inks: White, Cyan, Magenta, and Yellow

White ink is a base layer for vibrant prints on dark fabrics, CMYK inks contribute to the color gamut. In DTF direct to film printing, specialty inks like white ink, cyan ink, magenta ink, and yellow ink, along with ink to print a film, play crucial roles. White ink serves as a base layer, allowing for vibrant prints on dark fabrics. The CMYK inks contribute to the overall color gamut. Utilizing high-quality DTF ink ensures exceptional print quality with your DTF printing supplies, particularly when using a gang sheet builder.

DTF Transfer Process

Preparing DTF Transfers with Gang Sheets

Utilizing gang sheets is a smart way to maximize your direct to film printing efficiency. A gang sheet is a single sheet of where multiple designs are placed to optimize space; this is especially useful when using your . With a , you can arrange various designs onto a single sheet, reducing waste and saving on costs. This is an efficient method if you want to offer a to your customers.

Heat Press Techniques for DTF Transfers

Proper techniques are vital for successful applications in UV DTF printing. Consistent pressure and accurate temperature control are crucial for ensuring proper adhesion of the and onto the fabric. Experiment with different settings to find the optimal parameters for various fabric types and to achieve .

Warm Peel vs Hot Peel Transfers

The choice between warm peel and depends on the specific and personal preference. can be peeled immediately after heat pressing, while warm peel requires a brief cooling period. Proper peeling technique is essential to prevent damage to the and ensure a clean, professional finish when using .

Durability and Quality of DTF Prints

Factors Affecting Print Quality

Quality of ink, film, powder, printer maintenance, heat press settings, and color management are important. Several factors influence the quality of . The quality of the , , and are paramount. Proper maintenance, correct settings, and accurate color management all contribute to vibrant and durable prints with ink and adhesive. Paying attention to these details ensures consistently with your .

Long-term Durability of DTF Transfers

High-quality ink, adhesive, proper heat press application, and washing instructions ensure durability for your shop DTF creations. The long-term durability of hinges on several key aspects. Using ensures excellent wash resistance and prevents cracking or fading of the print. Proper application, following washing instructions, and selecting suitable fabrics can significantly extend the lifespan of prints.

Tips for Maintaining DTF Printing Equipment

Regular cleaning, following maintenance schedules, and proper storage are key to equipment longevity. Maintaining your equipment is essential for consistent performance and longevity. Regularly clean the print heads of your direct to film printer to prevent clogging and maintain quality. Adhere to the manufacturer's recommendations for maintenance schedules. Store and properly to prevent degradation. With proactive care, your direct to film printer will deliver reliable results using ink and adhesive.

Conclusion and Resources

Where to Buy DTF Supplies in the UK

Find reliable suppliers offering a wide range of DTF supplies, including 100m rolls, with good product quality, pricing, and customer support. Finding a reliable source for in the UK is crucial for any business. Look for suppliers that offer a wide range of , , , and options. Consider factors such as product quality, competitive pricing, and customer support when selecting your shop DTF vendor.

Online Resources for DTF Printing

Numerous online resources are available to support your journey. Online forums, tutorials, and manufacturer websites offer valuable information on maintenance, color management, and troubleshooting. These resources can help you stay up-to-date with the latest trends and best practices in .

Future Trends in DTF Printing

Expect improvements in ink, film, printer capabilities, automation, and sustainable practices. The future of looks promising with ongoing advancements in . Expect to see continued improvements in formulations, materials, and capabilities. Innovations in UV DTF, automation, and sustainable practices are likely to shape the landscape in the years to come.